Manufacturing Software Development Company

By streamlining your manufacturing processes, you can meet your revenue objective twice as quickly.

Our manufacturing software development firm provides customized solutions to assist you reach optimal efficiency and performance.

Best Manufacturing IT Solutions in the Business

Supplying reliable, high-quality manufacturing IT solutions spanning multiple time zones is something we are experts at Einnosys.

Our motto is always assisting those we serve in being relevant to the industry! Thus, we create IT solutions for manufacturing that suit each industrial the company’s unique needs and operations.

Manufacturing Software Solutions

Through specialised software consulting services, our staff of software developers and specialists provides you with continuous insight into your manufacturing processes, inventories, and how to allocate resources. Additional features like frictionless expansion and agility help you meet changing company demands and plan for future growth.

At eInnoSys, our manufacturing software solutions deliver tremendous value to businesses. Our manufacturing software solutions are made to tackle the unique problems that come with being a manufacturer, including inventory control, production scheduling, management of the supply chain, as well as quality assurance.

Exceptional IT Solutions for the Manufacturing Sector To Streamline Your Process

eInnoSys offers tailored IT services that tend to boost distribution networks, promote quality assurance, and improve efficiency for manufacturers.

ERP Software for Smart Manufacturing

With the help of our intelligent ERP software options, you can easily combine the many departments that make up a manufacturing company, such as banking, supply chain administration, control of inventories, manufacturing, and marketing.

Software for Maintenance Prediction

Using sophisticated machine learning and predictive analytics computations, it tracks machinery and uses patterns and oddities to predict likely failures or repairs required.

Software for Production Planning

Maximize the use of your resources—people, equipment, and machinery—by creating efficient production plans that take limits into account and optimize production schedules. Demand-Capacity

Upgrading Your Production Machinery’s Performance

Minimize operational interruptions and improve property life and system dependability by twenty percent to guarantee regular upkeep and minimize unforeseen downtime in the production process.

By implementing the fourth industrial revolution technology, the industry of manufacturing is going through a radical change.

- Astute Industries

- Science of Digital Twins

- Creating additives

To lessen their influence on the natural world, businesses are embracing sustainable methods more and more.

- Initiatives for Energy Conservation and Reuse

- Ecological Logistics Organizing

- Principles of the Economy

The production industry is using agile methods in response to shifting customer needs, technological advancements, and unanticipated obstacles in a time of rapid transformation.

- Adaptable Production Systems

- Cooperative Robots

- Teams from various departments.

- Analytics to anticipate

Cybersecurity risks are growing for the manufacturing sector as it gets more digitalized. Strong security protocols must be put in place to safeguard private information.

- Cybersecurity on the Network

- Constant Evaluation,

- Staff Formation, and

- Security for the Internet of Things

Advantages of Personalized Software Development for Manufacturing

To foster collaboration and boost productivity, our customised manufacturing software services give you the ability to securely share data across all of your industrial processes. Overseeing a committed staff of over 65 full-time programmers is the primary bonus that our clients love.

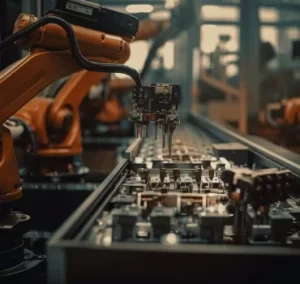

Robotics to reduce mistakes made by humans and provide consistency in manufacturing procedures

- Cutting-edge tracking systems to minimise expenses and manage assets

- Real-time systems for management with documentation and standardised procedures

- Intersections of various time zones and

- Efficient interaction for prompt support

Utilize Our Full-Cycle Software Creation Services for Industries that Need to Invent More Quickly.

With our comprehensive programming services for manufacturing firms, we are committed to collaborating with you to drive inventiveness, quicken expansion, and steer your company towards achievement.

Highly Featured Software Creation

Our expertise lies in developing trustworthy, expandable technologies that meet your specific company needs and provide optimal efficiency.

Incorporation of Technology

Integrate third-party apps or existing software options effortlessly to increase efficiency, enhance functionality, and simplify processes.

Transformation of Legacy Systems

With our application product renovation solutions, you may turn your antiquated manufacturing processes into cutting-edge, inventive ones that will enable you to remain in the industry for the long term.

We Are The Premier Option for Assistance with Consulting in Manufacturing Software

As a prominent and trustworthy name in the manufacturing technology assistance sector since the year 2013 eInnoSys can:

- Provide complete custom software creation solutions for the Manufacturing industry.

- Having worked in Manufacturing Technology for over 11 years, along with to having a decade of experience in creating customized software.

- Offer scalable alternatives for medical technologies.

- Use the Agile method, Swift, and Production Management techniques.

Process We Follow as a Healthcare Software Development Agency

Technology and Predictive Solutions for Businesses that Manufacture

By using the most recent advancements regarding technology and fashion, you may hold the top spot in the production sector.

To increase the safety, honesty, and provenance of the system’s operations, using specialised blockchain technology. By utilizing state-of-the-art decentralised technology, accuracy in data is maintained, product origin is tracked, as well as supply chain management is optimised.

Unleash the potential of machine learning and artificial intelligence to streamline procedures, improve making choices, and extract valuable insights from information. Install advanced equipment to boost productivity, ensure quality, and carry out routine checks.

Utilise the adaptability and capacity of online computing to streamline the company’s operations. Make use of cloud services for app development to improve teamwork, obtain immediate information, and deploy assets effectively.

Improve operational effectiveness, reduce interruptions, and enhance the performance of machinery by incorporating Internet of Things (IIoT) technologies in your manufacturing operations. With Industrial options, make use of intelligent sensors, statistical analysis of data, and automated upkeep.

The Manufacturing Sector’s Integrated IT Services Approach

Analysis of the Project

In order to lay the groundwork for a project to develop software that succeeds, thoroughly consider your production needs, difficulties, and objectives.

UX/UI Design

To enhance user experience and guarantee seamless integration with operational programmes, designers should prioritise simplicity of use when creating interfaces for users.

Progress

Make reliable, scalable, and customised applications that support your industrial processes with industry-leading technologies and industry standards.

Streamline And Improve The Way You Run Your Warehouse

Utilise technologies and environmentally friendly manufacturing methods to minimise your environmental effect and make the most use of the assets you have. Take advantage of contemporary innovations to reduce waste, maximise energy use, and execute environmentally friendly production activities.

Being one of the top suppliers of industrial services for software development, we supply a comprehensive range of solutions designed especially to meet the needs of manufacturing companies, delivering twice as much value at volume.