Summary

- Strategic IoT implementation is crucial for enterprises to move beyond pilot projects and achieve measurable ROI.

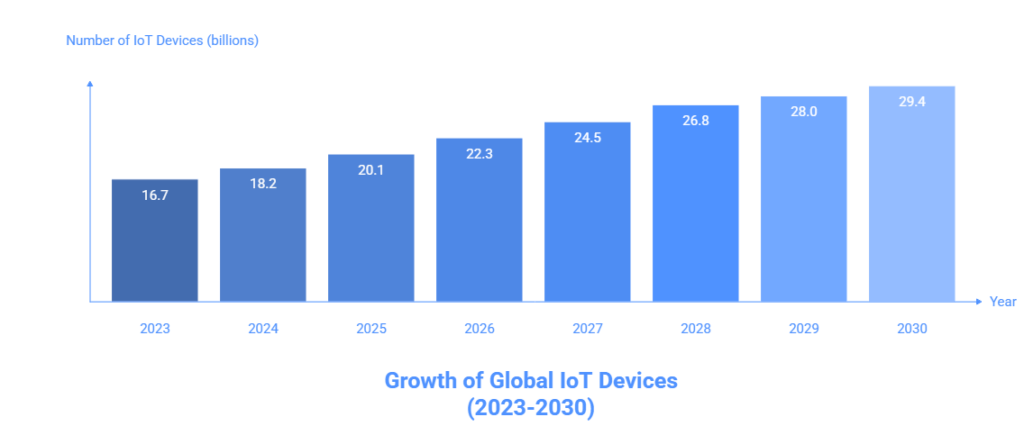

- The market is growing rapidly; Statista projects over 29 billion IoT devices by 2030, underscoring the urgency for a solid IoT implementation strategy. (Statista – 2024)

- Key challenges include securing the massive data surface, ensuring interoperability in IoT among disparate systems, and managing scale.

- Best practices involve a clear IoT roadmap, phased deployment (pilot to production), robust data governance, and proactive IoT change management.

- Success relies on aligning technology decisions (like edge computing for IoT) with specific business outcomes and careful vendor selection for IoT platforms.

Introduction

The promise of the Internet of Things (IoT) networked devices creating tidal waves of operational data is immense. However, moving from an exciting proof-of-concept to full-scale enterprise reality is often where companies stall. This journey requires more than just smart gadgets; it demands a comprehensive, business-aligned strategic IoT implementation. According to Statista (2024), the number of IoT devices worldwide is projected to increase from 16.7 billion in 2023 to over 29 billion by 2030, signaling a massive wave of connectivity that businesses must be prepared to manage.

This rapid expansion means that a reactive approach to deployment is a recipe for expensive failure. The real value is unlocked when the technology is integrated into the core business process, demanding a disciplined IoT implementation strategy that anticipates technical, organizational, and security hurdles.

For sectors ranging from Manufacturing & Industrial to Healthcare and Smart Cities, a well-defined approach separates the innovators from the simply curious. This article explores the delicate balance required for a successful transition from vision to execution, detailing the necessary strategic pillars for enterprise deployment.

The Strategic Imperative: Beyond the Pilot

The biggest hurdle many organizations face is translating a successful small-scale pilot project into a full-blown production environment. This step requires a shift from a technology-focused experiment to a business-driven initiative. The difference lies in robust planning, not simply bigger budgets.

Building a Business-Aligned IoT Roadmap

A successful IoT roadmap must start with a business need, not a technology one. Are you trying to improve asset utilization, reduce energy costs, or enable predictive maintenance? The answer dictates the technology stack.

- Define Success Metrics: Before deploying the first sensor, define the measuring the ROI of IoT projects. What operational improvements in dollars, time, or efficiency will this deliver? A clear ROI model moves the project out of the IT department and into the C-suite.

- Phased Deployment: The move from pilot to production IoT roadmap should be incremental and iterative. Start with a minimum viable product (MVP) focused on a single use case, then scale to adjacent areas or integrate more complex features. This allows for continuous learning and risk mitigation.

- Governance Framework: Establish clear ownership for the data, the platform, and the devices. This includes who is responsible for maintenance, updates, and monitoring. Without clear data governance for IoT, the project quickly becomes fragmented and unmanageable as scale increases.

Navigating the Complexities of IoT Integration Challenges

The IoT ecosystem is a mosaic of different devices, protocols, and platforms. Getting them to talk to each other without losing essential data is a significant task, often cited as one of the major IoT integration challenges.

We must think about more than just the devices. We must consider how the data from a temperature sensor in a refrigerated truck (relevant for Logistics & Supply Chain Management) gets integrated into an existing Enterprise Resource Planning (ERP) or Warehouse Management System (WMS). This is where interoperability in IoT becomes non-negotiable. Using open standards and APIs, rather than proprietary, locked-in solutions, can significantly reduce future integration headaches. Why tie your hands before the race has even started?

Technical Foundations: Scaling and Securing the Deployment

A production-ready IoT system must be designed for both security and massive scale from day one. Retrofitting these capabilities is costly and often ineffective.

Ensuring Robust IoT Scalability Strategies

Imagine a small pilot with 50 sensors. Now multiply that by 100, or even 1,000, as the deployment expands across a major industrial campus or a Smart City. The architecture needs to handle not only the device count but also the exponentially increasing data volume and velocity.

- Decentralization with Edge Computing: To handle the deluge of data locally, companies are increasingly turning to edge computing for IoT. This strategy involves processing time-sensitive or mission-critical data closer to the source (e.g., on a factory floor in the Automotive sector) before transmitting only relevant insights to the cloud. This reduces latency, saves bandwidth, and is critical for real-time control applications.

- Cloud Agnosticism: Choosing an architecture that isn’t completely locked into a single cloud provider offers flexibility. A hybrid approach often provides the best balance, using on-premise infrastructure for local control and the public cloud for analytics, storage, and global accessibility.

Overcoming IoT Security Challenges in Deployments

Security isn’t a feature; it’s the foundation. The vast, distributed nature of IoT devices, many with limited processing power and long operational lives, creates an enormous attack surface. The consequences of a breach in Healthcare (patient data) or Energy and Utilities (critical infrastructure) can be catastrophic. The task of overcoming IoT security challenges in deployments requires a multi-layered approach:

- Device-Level Security: Mandatory unique identities (certificates) for every device. Implement hardware root-of-trust where possible and ensure over-the-air (OTA) update mechanisms are secure to patch vulnerabilities rapidly.

- Network-Level Security: Isolate the IoT network from the corporate IT network using micro-segmentation. Employ secure gateways to act as intermediaries, inspecting and filtering traffic.

- Data Security: Data should be encrypted both at rest (storage) and in transit (transmission). Adherence to global and industry-specific regulations is vital for sectors like Retail and Agriculture, and Farming.

- Continuous Monitoring: Use Security Information and Event Management (SIEM) tools specific to IoT to detect anomalies in device behavior. A sudden surge in data transmission from a sensor can be an early indicator of compromise.

Organizational and Vendor Management: The Human Element

Technology rarely fails on its own; projects typically falter because of people, process, or partnership issues. A sound IoT deployment best practices guide addresses the soft skills as much as the hard tech.

Effective Vendor Selection and Partnership

Choosing the right technology partner is the make-or-break moment. The process of vendor selection for IoT platforms shouldn’t be based solely on who has the flashiest demo. It should be a rigorous assessment of their long-term viability, sector expertise, and openness.

- Longevity and Support: Is the platform provider financially stable? Will they be around in 5 or 10 years to support the system? A sensor deployed in a deep-sea oil rig or a remote agricultural field is expected to last for years, so the underlying support must, too.

- Ecosystem Flexibility: Does the platform integrate easily with the other devices and software you already use? A platform that forces you to rip and replace existing systems is often too expensive and disruptive to justify. Look for partners committed to IoT integration challenges through open standards.

- Service Level Agreements (SLAs): Clearly define uptime guarantees, response times for security incidents, and terms for data ownership. Remember, your data is your competitive advantage; make sure the contract reflects that.

Change Management and Workforce Readiness

Introducing IoT changes the way people work, often fundamentally. From machine operators to logistics managers, new skills and processes are needed. This is the heart of effective IoT change management.

- Upskilling and Training: Employees need to understand not just how to use the new technology, but why it matters and how it improves their jobs. For example, maintenance teams in the Research and Development/Tech Startups sector need training on diagnosing and maintaining edge gateways, not just the older PLC systems.

- Addressing Data Silos: IoT data, when merged with historical enterprise data, can unlock powerful new insights. However, organizational structures often resist this cross-departmental data sharing. The C-suite must lead the charge in breaking down these silos. An IoT implementation checklist for the C-suite must include data sharing mandates.

- Cultural Acceptance: The transition from reactive maintenance (fixing things when they break) to predictive maintenance (fixing things before they break) can be unsettling. A clear, continuous communication strategy is necessary to build trust and demonstrate the benefits. (McKinsey & Company – 2020)

Conclusion

The journey toward full-scale enterprise connectivity is complex, filled with technical, security, and organizational landmines. Yet, the rewards in efficiency, new business models, and operational intelligence make the effort imperative. By adopting a disciplined approach to strategic IoT implementation, focusing on a strong business case, securing the entire ecosystem, and actively managing organizational change, companies can successfully move from the lab to the load-bearing reality. The key is execution: a solid IoT implementation strategy is a living document, constantly refined by real-world data and experience.

Frequently Asked Questions

-

1. How to implement IoT in an enterprise effectively?

Effective how to implement IoT in an enterprise starts with a clear business outcome, not a technical tool. First, identify a high-value, measurable problem, for example, reducing downtime in a single production line, and design a small, focused pilot. Use this pilot to prove the ROI model and test the technology stack before scaling. The implementation should always follow a phased approach, ensuring that security and data governance frameworks are established early to support future expansion.

-

2. What is the best approach for balancing IoT challenges and benefits?

The best approach for balancing IoT challenges and benefits is to adopt a risk-aware, value-driven strategy. The highest benefits typically come with the highest risk (e.g., massive data streams, control over critical infrastructure). To manage this, apply rigorous IoT security best practices to the most critical assets, and use technologies like edge computing for IoT to mitigate network latency and data exposure risks. By proving the value early and scaling cautiously, you ensure that the benefits always outweigh the operational and security costs.

-

3. Can you provide an example of a real-world IoT deployment case study?

A great example of real-world IoT deployment case studies is in predictive maintenance within the Manufacturing & Industrial Sectors. A major automotive manufacturer installed sensors on key machinery (like presses and welding robots). These sensors continuously monitored vibration, temperature, and current draw. Instead of waiting for a machine to break or relying on scheduled maintenance, the system used machine learning to predict component failure hours or days in advance. This transition to predictive maintenance led to a significant reduction in unscheduled downtime and optimized maintenance staffing, proving a clear ROI.

-

4. What are the key items on an IoT implementation checklist for C-suite executives?

The IoT implementation checklist for the C-suite should focus on governance, budget, and organizational readiness, not technical specs. Key items include:

1) Business Alignment: Does the project directly align with top-line growth or core cost reduction goals?

2) Security Mandate: Are the budget and resources allocated to enforce end-to-end security and compliance?

3) Data Ownership: Is there a clear policy for data governance for IoT?

4) Change Management: Is there a funded plan for upskilling the workforce and addressing cultural resistance? The C-suite’s role is to ensure these non-technical barriers are removed.

-

5. What does a typical pilot to production IoT roadmap look like?

A typical pilot to production IoT roadmap involves three phases.

Phase 1 (Pilot): Focus on a single, isolated use case with minimal devices (e.g., 50–100 sensors). The goal is to validate the technology and prove the projected ROI.

Phase 2 (Minimal Viable Product/MVP): Scale the successful pilot to an entire site or region (e.g., 500–1,000 devices), incorporating initial IoT scalability strategies and integrating the data with one core enterprise system (e.g., ERP). The focus is on hardening security and operationalizing the platform.

Phase 3 (Full Production/Expansion): Deploy across the entire enterprise, integrate all necessary systems, and focus on optimizing data analytics and governance for continuous improvement.