Client Overview

A mid-sized manufacturing company specializing in chemical processing and fluid handling systems across Southeast Asia.

About the Company

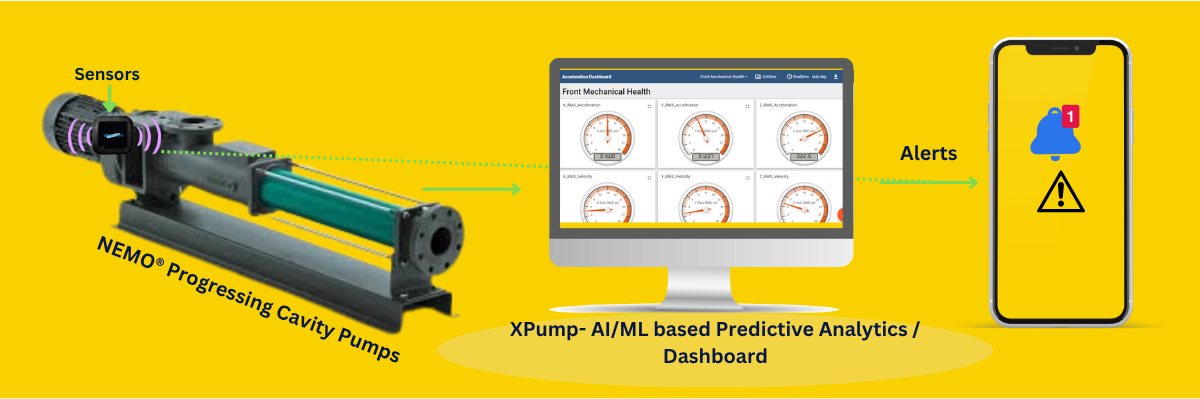

With decades of experience, the client operates multiple facilities where fluid transfer reliability is critical. The company depends heavily on NEMO Progressing Cavity Pumps for metering and transfer applications involving corrosive and abrasive fluids. Frequent pump failures and unplanned maintenance cycles disrupted productivity and increased operational costs.

Key Challenges

Unexpected pump breakdowns due to seal wear, dry-run conditions, and cavitation

Inability to capture early degradation signals from running equipment

Limited visibility into asset health across decentralized locations

Rising maintenance costs and spare part inventory

Our Xpump Solutions

We deployed AI xPump, a smart monitoring platform designed to enable predictive analytics on rotary equipment like NEMO® PCPs. The implementation included:

Sensor-Driven Monitoring

Enabling Real-Time Vibration, Temperature & Pressure Insights with IIoT

AI-Powered Analytics

Unlocking Predictive Intelligence from Historical Failure Patterns

Automated Condition Alerts

Detecting Torque Spikes & Seal Failures Before Downtime Strikes

Role-Based Dashboards

Delivering Actionable Insights to Reliability, Ops & Maintenance Teams

Cloud-Edge Scalability

Secure, Flexible Deployment Across Multi-Site Manufacturing Networks

Tech Stack

- xPump AI Engine (built on TensorFlow and Azure ML)

- OPC-UA & MQTT-based connectivity for PLC and sensor data ingestion

- Grafana-based visualization suite

- Microsoft Azure IoT Hub for edge/cloud sync

- RESTful APIs for ERP and CMMS integration

Business Impact

42% reduction

Data-driven maintenance planning

20% lower maintenance costs

Real-time visibility

Improved uptime

Download the case study here!

You’re one step away from building great software. This case study will help you learn more about how Einnosystech helps successful companies extend their tech teams.

Want to talk more? Get in touch today!

Email us sales@einnosystech.com or give us a call at +91 8160248065

Related case study